-

办公电话:0731-89743488

销售电话:13378911948

QQ:32045080

邮箱:32045080@qq.com

联系人:苏经理

WQ系列潜水排污栗主要用于市政工程、工业建筑、宾馆、医院、人防、矿山等行业,可用于排送带固体颗 粒及各种长纤维的污水、废水、雨水和城市生活用水。

WQ series submersible sewage pump is mainly used for municipal works, industrial buildings, hotels, hospitals, civil air defence, mines etc. Trades to drain off the sewage, waste water, rainwater and living water in cities containing Solid grains and various long fabrics.

配用电机功率(kW) Power of fitted motor(kW) 扬程(m) Head(m)

流量(m3/h) Capacity(m3/h)

潜水排污粟 Submersible sewage pump 排出口 径(mm) Drain aperture(mm)

使用条件 CONDITIONS OF USE

1、介质温度不应超过60T,介质密度sS1200Kg /m3,PH 值在5-9范围内。

2、运行时泵不得低于最低液位,参见安装尺寸图中的 “ ▼最低液位”(含自动冷却系统)。▽为无自动冷却系统时最低液位。

3、额定电压为380V,额定频率为50Hz。在额定电压和 额定频率的偏差不大于±5%时,电机才能正常运行。

4、通过泵的固体颗粒的最大直径不得大于泵体排出口直径的50%。

1. The medium temperature should not be over 60oC, the density 1200Kg /m3, and the PH value within 5-9.

2. During running, the pump must not be lower than the lowest liquid level, see ” ▼ lowest liquid level" in the drawing of installation dimensions(covering the automatic cooling system), means lowest liquid level without no automatic coo -ling system.

3. Rated voltage 380V, rated frequency 50Hz. The motor can run successfully only under the condition the deviations of both rated voltage and frequency are not over 土 5%.

4. The maximum diameter of the solid graingoing through the pump has not tobe larger than 50% of that of the pump outlet.

Sufi 方向 ROTATING DIRECTION

The impeller rotates CCW as viewed from the suction.

The impeller rotates CCW as viewed from the suction.

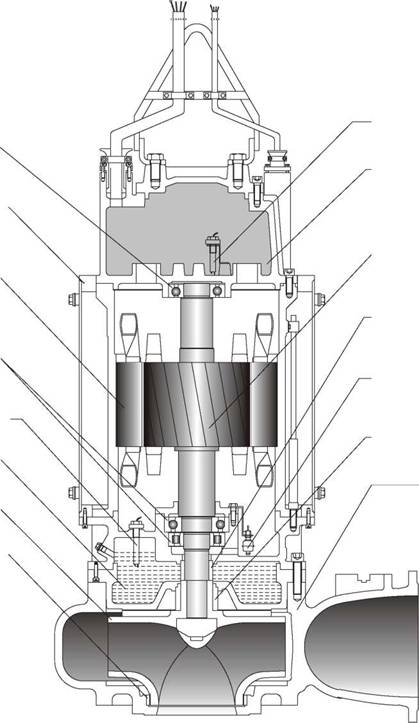

结构说明 STRUCTURES DESCRIPTION

轴承:

选用进口 SKF轴承或NTN轴承。其合理的轴承配置,能够延长栗的使用寿命。

冷却:

内装的冷却系统,不论电机是在液面上还是在液面 下,均能使泵正常工作。抽送液体的一部分从泵体循环 至冷却筒和机壳之间带走电机产生的热量。需要外部冷却时,冷却套可与泵体隔开,并与单独的冷却系统相连。

电机:

电机为F级绝缘,最高工作温度为155°C ,有效的密 封使电机防护等级为IPX8。

机械密封:

选用德国博格曼机械密封,两道机械密封串联相互独立工作。使电机与泵密封地隔开,为电机提供双重保 护。 泵侧材质为碳化鹤/碳化钨,电机侧材质为石墨順化硅。

油室:

油可润滑并冷却机械密封,并能阻止液体渗透至电 机的附加安全功能。内留的一定量空气可降低油室内压 力的积聚升高。

叶轮:

经过优化设计,以其最佳的流量和速度以最大效率输送液体使其不产生堵塞。每一个工况点都有相适应的 叶轮可供选择。 根据抽送的介质,有单流道、双流道、三叶片叶轮 可供选择。

泵体:

采用CAD/CAM技术,使泵体具有最高的效率和最小的磨损。

Imported SKF ofNTN bearing, which, with a reasonable configuration, can oxtend the duration ofthe pump.

The buit-in cooling system can have the pump normally work whether the motor is on or under the liquid surface. Apart of the liquid is extracted to bring out the beat produced by the motor from the pump circulation to the cooling barrel and to the pump casing and, when external cooling is required, the cooling sleeve may be separated from the pump casing and individually connected to the cooling system.

Of F class insulation, max. working temperatures 155oC, and of a protective grade IPX8 with the effective seal.

Use Bogman mechanical seal of Germany

The sealing material on the pump side is tungsten carbide/tungsten carbide while on the motor side, graphite/silicon carbide.

Oil can lubricate and cool the mechanical seal and realize the attached function of safety by preventing liquid from penetrating into the motor. The air of a certain amount left indide of the chamber can lower the pressure accumulatively raised.

With the optimized design, the impeller wil not be blocked up when to transport liquid with its optimum flow and rate and the maximum efficiency. There are suitable impellers at choice for every point of working condition.

There are single-geat, dual-geat and three-blade impellers available at choice per the medium to be extracted.

Use the know-how of CAD/CAM to make it ofmax. efficiency and min wearability.

WQ系列潜水排污栗主要用于市政工程、工业建筑、宾馆、医院、人防、矿山等行业,可用于排送带固体颗 粒及各种长纤维的污水、废水、雨水和城市生活用水。

WQ series submersible sewage pump is mainly used for municipal works, industrial buildings, hotels, hospitals, civil air defence, mines etc. Trades to drain off the sewage, waste water, rainwater and living water in cities containing Solid grains and various long fabrics.

配用电机功率(kW) Power of fitted motor(kW) 扬程(m) Head(m)

流量(m3/h) Capacity(m3/h)

潜水排污粟 Submersible sewage pump 排出口 径(mm) Drain aperture(mm)

使用条件 CONDITIONS OF USE

1、介质温度不应超过60T,介质密度sS

2、运行时泵不得低于最低液位,参见安装尺寸图中的 “ ▼最低液位”(含自动冷却系统)。▽为无自动冷却系统时最低液位。

3、额定电压为380V,额定频率为50Hz。在额定电压和 额定频率的偏差不大于±5%时,电机才能正常运行。

4、通过泵的固体颗粒的最大直径不得大于泵体排出口直径的50%。

1. The medium temperature should not be over 60oC, the density

2. During running, the pump must not be lower than the lowest liquid level, see ” ▼ lowest liquid level" in the drawing of installation dimensions(covering the automatic cooling system), means lowest liquid level without no automatic coo -ling system.

3. Rated voltage 380V, rated frequency 50Hz. The motor can run successfully only under the condition the deviations of both rated voltage and frequency are not over 土 5%.

4. The maximum diameter of the solid graingoing through the pump has not tobe larger than 50% of that of the pump outlet.

Sufi 方向 ROTATING DIRECTION

![]() The impeller rotates CCW as viewed from the suction.

The impeller rotates CCW as viewed from the suction.

结构说明 STRUCTURES DESCRIPTION

轴承:

选用进口 SKF轴承或NTN轴承。其合理的轴承配置,能够延长栗的使用寿命。

冷却:

内装的冷却系统,不论电机是在液面上还是在液面 下,均能使泵正常工作。抽送液体的一部分从泵体循环 至冷却筒和机壳之间带走电机产生的热量。需要外部冷却时,冷却套可与泵体隔开,并与单独的冷却系统相连。

电机:

电机为F级绝缘,最高工作温度为

机械密封:

选用德国博格曼机械密封,两道机械密封串联相互独立工作。使电机与泵密封地隔开,为电机提供双重保 护。 泵侧材质为碳化鹤/碳化钨,电机侧材质为石墨順化硅。

油室:

油可润滑并冷却机械密封,并能阻止液体渗透至电 机的附加安全功能。内留的一定量空气可降低油室内压 力的积聚升高。

叶轮:

经过优化设计,以其最佳的流量和速度以最大效率输送液体使其不产生堵塞。每一个工况点都有相适应的 叶轮可供选择。 根据抽送的介质,有单流道、双流道、三叶片叶轮 可供选择。

泵体:

采用CAD/CAM技术,使泵体具有最高的效率和最小的磨损。

Imported SKF ofNTN bearing, which, with a reasonable configuration, can oxtend the duration ofthe pump.

The buit-in cooling system can have the pump normally work whether the motor is on or under the liquid surface. Apart of the liquid is extracted to bring out the beat produced by the motor from the pump circulation to the cooling barrel and to the pump casing and, when external cooling is required, the cooling sleeve may be separated from the pump casing and individually connected to the cooling system.

Of F class insulation, max. working temperatures 155oC, and of a protective grade IPX8 with the effective seal.

Use Bogman mechanical seal of

The sealing material on the pump side is tungsten carbide/tungsten carbide while on the motor side, graphite/silicon carbide.

Oil can lubricate and cool the mechanical seal and realize the attached function of safety by preventing liquid from penetrating into the motor. The air of a certain amount left indide of the chamber can lower the pressure accumulatively raised.

With the optimized design, the impeller wil not be blocked up when to transport liquid with its optimum flow and rate and the maximum efficiency. There are suitable impellers at choice for every point of working condition.

There are single-geat, dual-geat and three-blade impellers available at choice per the medium to be extracted.

Use the know-how of CAD/CAM to make it ofmax. efficiency and min wearability.

泵与电机同轴,轴端密封装置,使轴不与抽送介质相接触,保护轴不受腐蚀。

转轴悬伸设计得尽量短,降低转轴的挠度,并减小 振动,延长机械密封和轴承的使用寿命,降低运行噪音。

定子内嵌有三个串联的热控开关。常温时为“常闭” 状态,当定子温度达到

油室内装有漏水探头,用作漏水检测。当泵侧机械 密封泄漏,油室内的油水比例达到一定浓度,油水探头 就发出报警信号(指示灯亮)并自动切断电源,使栗停止工作。

维修人员应及时更换油室内的油,并检查和更换泵 侧机械密封。

电机功率不低于30kW的泵,接线腔内均装有漏水探 头,检测电缆密封是否泄漏。

当电机侧机械密封泄漏、液体进入浮子开关室、渗 入液体达到一定高度时,浮子开关会发出报警信号(指 示灯亮)并停栗,维修人员应进行检修并更换电机侧机械密封。

电控柜有对电机缺相进行检测的功能,以防缺相烧 坏电机。

The pump is coaxial with the motor and the sealing device on the end of the shaft prevents against contacting with the medium to protect is from corrosion.

The as short as possible designed stretched rotating shaft can be reduced with its deflection and vibration, extend the duration of both mechanical seal and bearing and lower the noise at running.

Inside of the stator there are three inlaid series heat-con- trol switches, which are in the state of "N.O." at the normal temperature and opened when the temperature on the stator gets to 125°G.

A water-leakage probe is mounted inside the oil chamber to check water leakage and it will give a warning signal(the indicator lights), when the mechanical seal on the pump side leaks and the oil-water ratio in the oil chamber reaches a certain concentration, to automatic ally cut off the power to stop the work ofthe pump.

Serviceman should replace the oil timely and check the mechanical seal on the pump side and replace it it necessary.

All the wiring box of the motor with a power not lower than 30kW is mounted with a leakage probe to check if a leak with the cable seal.

The float switch will give a warning sigual(the indicator lights), when leakage occurs on the mechanical seal on the motor side, the liquid goes into the switch room and reaches a certainheight, to stop the pump. Serviceman should check the mechanical seal and replace it if necessary.

The function to check if the motor lack of phase is available withthe electric control cabinet so as to prevent it from burning due any lack o

|

序号 |

型号 |

排出口径 |

流量 Capacity |

扬程 |

转速 |

功率 |

效率 |

重量 | |

|

Outlet diameter |

Head |

Speed |

Power |

Efficiency |

Weight | ||||

|

No. |

Type |

(mm) |

(m3/h) |

(L/s) |

(m) |

(r/min) |

(kW) |

(%) |

(Kg) |

|

10 |

2.8 |

10 |

48 |

||||||

|

50WQ |

50 |

15 |

4.2 |

8 |

2825 |

0.75 |

52 |

30 | |

|

20 |

5.6 |

7 |

56 |

||||||

|

10 |

2.8 |

14 |

48 |

||||||

|

2 |

50WQ |

50 |

15 |

4.2 |

12 |

2825 |

1.1 |

52 |

32 |

|

20 |

5.6 |

10 |

56 |

||||||

|

10 |

2.8 |

18 |

48 |

||||||

|

3 |

50WQ15-16-1.5 |

50 |

15 |

4.5 |

16 |

2840 |

1.5 |

52 |

40 |

|

20 |

6.9 |

10 |

56 |

||||||

|

10 |

2.8 |

25 |

48 |

||||||

|

4 |

50WQ15-22-2.2 |

50 |

15 |

4.2 |

22 |

2840 |

2.2 |

52 |

45 |

|

20 |

6.9 |

16 |

56 |

||||||

|

10 |

2.8 |

33 |

45 |

||||||

|

5 |

50WQ15-30-3 |

50 |

15 |

4.2 |

30 |

2880 |

3 |

50 |

55 |

|

20 |

6.9 |

20 |

54 |

||||||

|

20 |

5.6 |

28 |

43 |

||||||

|

6 |

50WQ25-25-4 |

50 |

25 |

6.9 |

25 |

2880 |

4 |

48 |

65 |

|

40 |

11.1 |

18 |

53 |

||||||

|

20 |

5.6 |

35 |

43 |

||||||

|

7 |

50WQ25-32-5.5 |

50 |

25 |

6.9 |

32 |

1440 |

5.5 |

48 |

90 |

|

40 |

11.1 |

25 |

55 |

||||||

|

20 |

5.6 |

38 |

43 |

||||||

|

8 |

50WQ25-36-7.5 |

50 |

25 |

6.9 |

36 |

1440 |

7.5 |

48 |

105 |

|

40 |

11.1 |

33 |

55 |

||||||

|

20 |

5.6 |

12 |

50 |

||||||

|

9 |

65WQ |

65 |

30 |

8.3 |

10 |

1420 |

2.2 |

62 |

55 |

|

45 |

12.5 |

8 |

64 |

||||||

|

20 |

5.6 |

17 |

50 |

||||||

|

10 |

65WQ30-15-3 |

65 |

30 |

8.3 |

15 |

1420 |

3 |

62 |

65 |

|

45 |

12.5 |

12 |

64 |

||||||

|

20 |

5.6 |

24 |

44 |

||||||

|

11 |

65WQ30-22-4 |

65 |

30 |

8.3 |

22 |

1440 |

4 |

52 |

75 |

|

45 |

12.5 |

16 |

57 |

||||||

|

20 |

5.6 |

32 |

44 |

||||||

|

12 |

65WQ30-30-5.5 |

65 |

30 |

8.3 |

30 |

1440 |

5.5 |

52 |

100 |

|

45 |

12.5 |

22 |

57 |

||||||

|

20 |

5.6 |

37 |

44 |

||||||

|

13 |

65WQ30-35-7.5 |

65 |

30 |

8.3 |

35 |

1440 |

7.5 |

50 |

115 |

|

45 |

12.5 |

30 |

57 |

||||||

|

40 |

11.1 |

10 |

56 |

||||||

|

14 |

80WQ |

80 |

50 |

13.9 |

8 |

1420 |

2.2 |

60 |

65 |

|

75 |

20.8 |

6 |

63 |

||||||

|

40 |

11.1 |

13 |

56 |

||||||

|

15 |

80WQ |

80 |

50 |

13.9 |

10 |

1420 |

3 |

60 |

75 |

|

75 |

20.8 |

8 |

62 |

||||||

|

40 |

11.1 |

18 |

55 |

||||||

|

16 |

80WQ50-15-4 |

80 |

50 |

13.9 |

15 |

1440 |

4 |

58 |

85 |

|

75 |

20.8 |

10 |

60 |

||||||

|

40 |

11.1 |

23 |

48 |

||||||

|

17 |

80WQ50-20-5.5 |

80 |

50 |

13.9 |

20 |

1440 |

5.5 |

55 |

110 |

|

75 |

20.8 |

16 |

66 |

||||||

|

40 |

11.1 |

28 |

48 |

||||||

|

18 |

80WQ50-25-7.5 |

80 |

50 |

13.9 |

25 |

1440 |

7.5 |

55 |

125 |

|

75 |

20.8 |

21 |

63 |

||||||

|

40 |

11.1 |

40 |

48 |

||||||

|

19 |

80WQ50-35-11 |

80 |

50 |

13.9 |

35 |

2900 |

11 |

55 |

180 |

|

75 |

20.8 |

27 |

63 |

||||||

|

40 |

11.1 |

42 |

46 |

||||||

|

20 |

80WQ50-40-15 |

80 |

50 |

13.9 |

40 |

2900 |

15 |

52 |

205 |

|

75 |

20.8 |

37 |

60 |

||||||

|

序号 |

型号 |

排出口径 |

流量 Capacity |

扬程 |

转速 |

功率 |

效率 |

重量 | |

|

Outlet diameter |

Head |

Speed |

Power |

Efficiency |

Weight | ||||

|

No. |

Type |

(mm) |

(m3/h) |

(L/s) |

(m) |

(r/min) |

(kW) |

(%) |

(Kg) |

|

65 |

18.1 |

8 |

62 |

||||||

|

21 |

100WQ |

100 |

80 |

22.2 |

7 |

1420 |

3 |

64 |

85 |

|

120 |

33.3 |

5 |

60 |

||||||

|

65 |

18.1 |

12 |

62 |

||||||

|

22 |

100WQ |

100 |

80 |

22.2 |

10 |

1440 |

4 |

64 |

95 |

|

120 |

33.3 |

7 |

62 |

||||||

|

65 |

18.1 |

15 |

58 |

||||||

|

23 |

100WQ80-13-5.5 |

100 |

80 |

22.2 |

13 |

1440 |

5.5 |

64 |

120 |

|

120 |

33.3 |

10 |

67 |

||||||

|

65 |

18.1 |

21 |

58 |

||||||

|

24 |

100WQ80-18-7.5 |

100 |

80 |

22.2 |

18 |

1440 |

7.5 |

64 |

135 |

|

120 |

33.3 |

13 |

67 |

||||||

|

65 |

18.1 |

28 |

58 |

||||||

|

25 |

100WQ80-24-11 |

100 |

80 |

22.2 |

24 |

2900 |

11 |

64 |

190 |

|

120 |

33.3 |

20 |

67 |

||||||

|

65 |

18.1 |

35 |

54 |

||||||

|

26 |

100WQ80-32-15 |

100 |

80 |

22.2 |

32 |

2900 |

15 |

58 |

215 |

|

120 |

33.3 |

25 |

62 |

||||||

|

65 |

18.1 |

40 |

50 |

||||||

|

27 |

100WQ80-36-18.5 |

100 |

80 |

22.2 |

36 |

2900 |

18.5 |

55 |

280 |

|

120 |

33.3 |

30 |

60 |

||||||

|

65 |

18.1 |

45 |

50 |

||||||

|

28 |

100WQ80-40-22 |

100 |

80 |

22.2 |

40 |

2900 |

22 |

55 |

290 |

|

120 |

33.3 |

35 |

60 |

||||||

|

100 |

27.8 |

9 |

63 |

||||||

|

29 |

150WQ |

150 |

150 |

41.7 |

7 |

1440 |

5.5 |

72 |

130 |

|

220 |

61.1 |

5 |

70 |

||||||

|

100 |

27.8 |

12 |

63 |

||||||

|

30 |

150WQ |

150 |

150 |

41.7 |

10 |

1440 |

7.5 |

72 |

150 |

|

220 |

61.1 |

7 |

70 |

||||||

|

100 |

27.8 |

18 |

67 |

||||||

|

31 |

150WQ150-15-11 |

150 |

150 |

41.7 |

15 |

1460 |

11 |

72 |

215 |

|

220 |

61.1 |

11 |

68 |

||||||

|

100 |

27.8 |

23 |

60 |

||||||

|

32 |

150WQ150-20-15 |

150 |

150 |

41.7 |

20 |

1460 |

15 |

68 |

240 |

|

220 |

61.1 |

17 |

64 |

||||||

|

100 |

27.8 |

28 |

60 |

||||||

|

33 |

150WQ150-25-18.5 |

150 |

150 |

41.7 |

25 |

1470 |

18.5 |

68 |

300 |

|

220 |

61.1 |

19 |

64 |

||||||

|

100 |

27.8 |

33 |

60 |

||||||

|

34 |

150WQ150-30-22 |

150 |

150 |

41.7 |

30 |

1470 |

22 |

65 |

320 |

|

200 |

55.6 |

25 |

68 |

||||||

|

100 |

27.8 |

42 |

60 |

||||||

|

35 |

150WQ150-40-30 |

150 |

150 |

41.7 |

40 |

1470 |

30 |

65 |

580 |

|

200 |

55.6 |

33 |

68 |

||||||

|

100 |

27.8 |

47 |

55 |

||||||

|

36 |

150WQ150-45-37 |

150 |

150 |

41.7 |

45 |

1470 |

37 |

62 |

650 |

|

200 |

55.6 |

38 |

65 |

||||||

|

100 |

27.8 |

52 |

55 |

||||||

|

37 |

150WQ150-50-45 |

150 |

150 |

41.7 |

50 |

1470 |

45 |

62 |

750 |

|

200 |

55.6 |

47 |

65 |

||||||

|

80 |

22.2 |

62 |

53 |

||||||

|

38 |

150WQ100-60-55 |

150 |

100 |

27.8 |

60 |

1470 |

55 |

60 |

850 |

|

150 |

41.7 |

56 |

63 |

||||||

|

250 |

69.4 |

8 |

72 |

||||||

|

39 |

200WQ |

200 |

300 |

83.3 |

7 |

1460 |

11 |

74 |

280 |

|

400 |

111.1 |

6 |

69 |

||||||

|

250 |

69.4 |

11 |

72 |

||||||

|

40 |

200WQ |

200 |

300 |

83.3 |

10 |

1460 |

15 |

74 |

300 |

|

400 |

111.1 |

8 |

69 |

||||||

|

序号 No. |

型号 Type |

排出口径 Outlet diameter (mm) |

流量 Capacity |

扬程 Head (m) |

转速 Speed (r/min) |

功率 Power (kW) |

效率 Efficiency (%) |

重量 Weight (Kg) | |

|

(m3/h) |

(L/s) | ||||||||

|

500 |

138.9 |

8 |

69 |

||||||

|

61 |

300WQ |

300 |

600 |

166.7 |

7 |

1470 |

22 |

65 |

660 |

|

750 |

208.3 |

6 |

61 |

||||||

|

550 |

152.8 |

13 |

72 |

||||||

|

62 |

300WQ |

300 |

700 |

194.4 |

11 |

980 |

30 |

78 |

780 |

|

1000 |

277.8 |

8 |

77 |

||||||

|

550 |

152.8 |

16 |

72 |

||||||

|

63 |

300WQ700-14-37 |

300 |

700 |

194.4 |

14 |

980 |

37 |

78 |

880 |

|

1000 |

277.8 |

10 |

77 |

||||||

|

550 |

152.8 |

18 |

72 |

||||||

|

64 |

300WQ700-16-45 |

300 |

700 |

194.4 |

16 |

980 |

45 |

78 |

1150 |

|

1000 |

277.8 |

12 |

77 |

||||||

|

550 |

152.8 |

21 |

70 |

||||||

|

65 |

300WQ700-19-55 |

300 |

700 |

194.4 |

19 |

980 |

55 |

75 |

1215 |

|

1000 |

277.8 |

14 |

73 |

||||||

|

800 |

222.2 |

23 |

75 |

||||||

|

66 |

300WQ1000-20-75 |

300 |

1000 |

277.8 |

20 |

990 |

75 |

82 |

1530 |

|

1400 |

388.9 |

15 |

80 |

||||||

|

800 |

222.2 |

27 |

75 |

||||||

|

67 |

300WQ1000-24-90 |

300 |

1000 |

277.8 |

24 |

990 |

90 |

82 |

1650 |

|

1400 |

388.9 |

18 |

80 |

||||||

|

800 |

222.2 |

31 |

75 |

||||||

|

68 |

300WQ1000-28-110 |

300 |

1000 |

277.8 |

28 |

1480 |

110 |

82 |

1720 |

|

1400 |

388.9 |

20 |

80 |

||||||

|

800 |

222.2 |

38 |

75 |

||||||

|

69 |

300WQ1000-35-132 |

300 |

1000 |

277.8 |

35 |

1480 |

132 |

80 |

1800 |

|

1400 |

388.9 |

27 |

82 |

||||||

|

1000 |

277.8 |

7 |

75 |

||||||

|

70 |

350WQ |

350 |

1200 |

333.3 |

6 |

730 |

30 |

72 |

850 |

|

1500 |

416.7 |

5 |

70 |

||||||

|

1000 |

277.8 |

9 |

76 |

||||||

|

71 |

350WQ1200-8-37 |

350 |

1200 |

333.3 |

8 |

740 |

37 |

75 |

950 |

|

1500 |

416.7 |

6 |

70 |

||||||

|

900 |

250 |

11 |

67 |

||||||

|

72 |

350WQ1100-10-45 |

350 |

1100 |

305.6 |

10 |

740 |

45 |

70 |

1250 |

|

1500 |

416.7 |

7 |

68 |

||||||

|

900 |

250 |

14 |

69 |

||||||

|

73 |

350WQ1100-12-55 |

350 |

1100 |

305.6 |

12 |

740 |

55 |

71 |

1320 |

|

1500 |

416.7 |

8 |

66 |

||||||

|

900 |

250 |

19 |

70 |

||||||

|

74 |

350WQ1100-16-75 |

350 |

1100 |

305.6 |

16 |

980 |

75 |

75 |

1650 |

|

1500 |

416.7 |

12 |

72 |

||||||

|

900 |

250 |

24 |

70 |

||||||

|

75 |

350WQ1100-20-90 |

350 |

1100 |

305.6 |

20 |

980 |

90 |

75 |

1770 |

|

1500 |

416.7 |

15 |

72 |

||||||

|

900 |

250 |

30 |

72 |

||||||

|

76 |

350WQ1100-25-110 |

350 |

1100 |

305.6 |

25 |

980 |

110 |

76 |

1840 |

|

1500 |

416.7 |

18 |

73 |

||||||

|

900 |

250 |

35 |

72 |

||||||

|

77 |

350WQ1100-30-132 |

350 |

1100 |

305.6 |

30 |

980 |

132 |

75 |

1920 |

|

1500 |

416.7 |

24 |

79 |

||||||

|

900 |

250 |

40 |

70 |

||||||

|

78 |

350WQ1100-36-160 |

350 |

1100 |

305.6 |

36 |

980 |

160 |

75 |

2700 |

|

1500 |

416.7 |

28 |

80 |

||||||

|

1200 |

333.3 |

35 |

75 |

||||||

|

79 |

350WQ1500-30-185 |

350 |

1500 |

416.7 |

30 |

980 |

185 |

80 |

2800 |

|

2000 |

555.6 |

24 |

77 |

||||||

|

1200 |

333.3 |

38 |

75 |

||||||

|

80 |

350WQ1500-32-200 |

350 |

1500 |

416.7 |

32 |

740 |

200 |

80 |

2850 |

|

2000 |

555.6 |

25 |

78 |

||||||

|

序号 No. |

型号 Type |

排出口径 Outlet diameter (mm) |

流量 Capacity |

扬程 Head (m) |

转速 Speed (r/min) |

功率 Power (kW) |

效率 Efficiency (%) |

重量 Weight (Kg) | |

|

(m3/h) |

(L/s) | ||||||||

|

1500 |

416.7 |

10 |

80 |

||||||

|

102 |

500WQ2000-7-55 |

500 |

2000 |

555.6 |

7 |

740 |

55 |

76.2 |

1950 |

|

3000 |

833.3 |

4 |

68 |

||||||

|

1800 |

500 |

10 |

75 |

||||||

|

103 |

500WQ2200-8-75 |

500 |

2200 |

611.1 |

8 |

980 |

75 |

70 |

2150 |

|

3000 |

833.3 |

5 |

65 |

||||||

|

1800 |

500 |

13 |

78 |

||||||

|

104 |

500WQ2200-10-90 |

500 |

2200 |

611.1 |

10 |

990 |

90 |

72 |

1920 |

|

3000 |

833.3 |

7 |

68 |

||||||

|

1800 |

500 |

15 |

75 |

||||||

|

105 |

500WQ2200-12-110 |

500 |

2200 |

611.1 |

12 |

990 |

110 |

72 |

1990 |

|

3000 |

833.3 |

8 |

68 |

||||||

|

1800 |

500 |

17 |

70 |

||||||

|

106 |

500WQ2200-15-132 |

500 |

2200 |

611.1 |

15 |

990 |

132 |

75 |

2070 |

|

3000 |

833.3 |

10 |

68 |

||||||

|

2000 |

555.6 |

14 |

78 |

||||||

|

107 |

500WQ3000-11-132 |

500 |

3000 |

833.3 |

11 |

745 |

132 |

75 |

2210 |

|

4000 |

1111.1 |

8 |

72 |

||||||

|

2000 |

555.6 |

21 |

78 |

||||||

|

108 |

500WQ3000-13-160 |

500 |

3000 |

833.3 |

13 |

745 |

160 |

75 |

2900 |

|

4000 |

1111.1 |

9 |

72 |

||||||

|

2000 |

555.6 |

22 |

75 |

||||||

|

109 |

500WQ3000-15-185 |

500 |

3000 |

833.3 |

15 |

745 |

185 |

72 |

2950 |

|

4000 |

1111.1 |

11 |

70 |

||||||

|

2000 |

555.6 |

23 |

75 |

||||||

|

110 |

500WQ3000-16-200 |

500 |

3000 |

833.3 |

16 |

745 |

200 |

72 |

3000 |

|

4000 |

1111.1 |

12 |

70 |

||||||

|

2000 |

555.6 |

26 |

70 |

||||||

|

111 |

500WQ3000-18-220 |

500 |

3000 |

833.3 |

18 |

745 |

220 |

75 |

3200 |

|

4000 |

1111.1 |

14 |

73 |

||||||

|

2000 |

555.6 |

29 |

70 |

||||||

|

112 |

500WQ3000-21-250 |

500 |

3000 |

833.3 |

21 |

745 |

250 |

77 |

3400 |

|

4000 |

1111.1 |

16 |

75 |

||||||

|

2000 |

555.6 |

32 |

70 |

||||||

|

113 |

500WQ3000-24-280 |

500 |

3000 |

833.3 |

24 |

745 |

280 |

77 |

3600 |

|

4000 |

1111.1 |

18 |

75 |

||||||

|

2500 |

694.4 |

10 |

70 |

||||||

|

114 |

600WQ3000-8-110 |

600 |

3000 |

833.3 |

8 |

590 |

110 |

68 |

2900 |

|

4000 |

1111.1 |

6 |

65 |

||||||

|

2500 |

694.4 |

12 |

70 |

||||||

|

115 |

600WQ3000-10-132 |

600 |

3000 |

833.3 |

10 |

590 |

132 |

75 |

3000 |

|

4000 |

1111.1 |

8 |

72 |

||||||

|

3000 |

833.3 |

13 |

78 |

||||||

|

116 |

600WQ4000-10-160 |

600 |

4000 |

1111.1 |

10 |

745 |

160 |

75 |

3000 |

|

5000 |

1388.9 |

8 |

73 |

||||||

|

3000 |

833.3 |

15 |

78 |

||||||

|

117 |

600WQ4000-11-185 |

600 |

4000 |

1111.1 |

11 |

745 |

185 |

75 |

3050 |

|

6000 |

1666.7 |

6 |

65 |

||||||

|

3000 |

833.3 |

16 |

75 |

||||||

|

118 |

600WQ4000-12-200 |

600 |

4000 |

1111.1 |

12 |

745 |

200 |

72 |

3100 |

|

6000 |

1666.7 |

7 |

65 |

||||||

|

3000 |

833.3 |

18 |

77 |

||||||

|

119 |

600WQ4000-14-220 |

600 |

4000 |

1111.1 |

14 |

745 |

220 |

75 |

3300 |

|

6000 |

1666.7 |

9 |

72 |

||||||

|

3000 |

833.3 |

21 |

75 |

||||||

|

120 |

600WQ4000-16-250 |

600 |

4000 |

1111.1 |

16 |

745 |

250 |

78 |

3500 |

|

6000 |

1666.7 |

10 |

73 |

||||||

|

3000 |

833.3 |

23 |

75 |

||||||

|

121 |

600WQ4000-18-280 |

600 |

4000 |

1111.1 |

18 |

745 |

280 |

77 |

3750 |

|

6000 |

1666.7 |

11 |

72 |

||||||

|

3000 |

833.3 |

25 |

75 |

||||||

|

122 |

600WQ4000-20-315 |

600 |

4000 |

1111.1 |

20 |

745 |

315 |

77 |

4000 |

|

6000 |

1666.7 |

13 |

73 |

||||||

厂址:湖南省长沙市雨花区井奎路17号(原长沙工业泵总厂) 联系电话:0731-84168878 传真: 0731-86456785 24小时联系电话:15874066888

EMAIL:32045080@qq.com Copyright ? 20012-2021 湖南安德理斯泵业有限公司 All rights reserved.